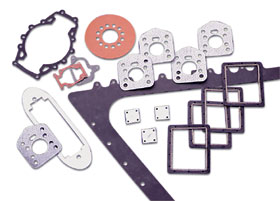

Elastomeric Products – Seals & Gaskets

Custom engineered seals & gaskets that are designed specifically for your application.

Seal Science, Inc. has always been able to provide its customers with the best possible solution at the most competitive price by offering tremendous value, quality and reliability. With excellent material science, design engineering, application experience, and precision manufacturing techniques at its core, SSI delivers engineers a complete resource for sealing requirements.

Our seals & gaskets are designed for your specific application and are used widely in critical assemblies when failure is not an option. Our elastomeric products can be seen in the following industries: Aerospace, Aviation, , Military/Defense, Automotive, Chemical processing, Medical, Semiconductor, Oil/Gas Exploration & Industrial Flow Controls.

- Experts with Close Tolerances

- Widest Material Selection

- CAD, CNC, EDM Mold Making

- Metal/Plastic/PTFE Substrates

- Injection, Transfer, and Compression Molding

- Material Testing

- Standard and Custom Compounds

- Rubber, Plastics, Foams

- Small to Large Sizes and Quantities

- ESD/RFI Composites

- High Speed Machines

- Rapid Delivery

- Design for Gasket Factor Performance

- Adhesive Backing

- LMA Materials

- Military, Commercial, Drone, Satellite, Missile & Interior Seals

- Bulb Seals

- Door, Window, Hatch, Gap Seals

- Fire Barriers

- Fabric and Composite Reinforcements

- Conductive Elastomers for RAM, ESD, EMI, RFI applications

- Aerodynamic Seals

- Electronic Wave, Vibration Control & Moisture Sealing

- Any Size; Micro to Very Large

- Customer or Seal Science Design

- Many materials or custom compounds to meet your requirements

- Co-Molding

- Complete Assemblies

- Design Engineers and Material Specialists On-Site

- MIL-DT:-83528

- EMI/RFI/ESD Shielding

- Radar Absorbing Materials (RAM)

- 0.2 Ohm-Cm to 40,000,000 Ohm-Cm Materials

- Test Verified Conductivity and Resistivity

- Wide Temperature Ranges

- Molded and/or Die Cut Shapes

- Spring Seals

- Rod and Piston Seals

- Piston Rings

- Rotary Seals

- Friction Limiting and Heat Resistant

- Standard and Custom Materials

- Mil Spec and Industrial Sizes

Seal Science handles many different types of seals. See some of them below.

- Hydraulic Seals

- Pneumatic Seals

- Rod Seals

- Rotary Seals

- Spring Seals

- Dynamic Seals

- Standard and Custom Materials

- Mil Spec and Industrial Sizes

- 20-300 Ton Capabilities

- Insert Molding

- Engineered Materials

- Hytrel®, Santoprene®, and Kraton®

- Rapid Prototyping Available

- Custom Designs

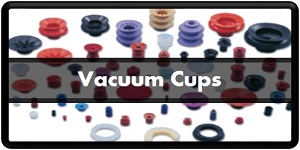

- Over 100 Compounds

- Large Inventory

- Standard Sizes 2mm to 170mm; Specials up to 500mm

- Conductive or Non-Staining

- High and Low Temperature

- Expert Assistance

- Custom Designs

Seal Science Capabilities

With over 30 years of experience, we are able to provide our clients with the confidence and support required for high-end critical sealing applications.

- Rubber to Metal Bonding

- Extruding

- Compression Molding

- Hand Fabrication

- Injection Molding

- Liquid Injection Molding

- Plastic and Metal Machining

- Plastic Injection

- Mold and Tool Making

- Stamping

- Die-cutting

- Precision Grinding

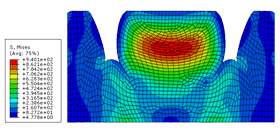

- Extreme Temperatures

- Dynamic Wear/Friction

- Chemical Resistance

- High Pressure

- Vacuum

- Precision Tolerances

- EMI/RFI/ESD Shielding

- Conductive

- Bonding

- Purity