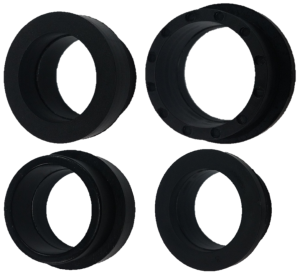

Custom Polyurethane Bushings

Seal Science is an industry leader in custom rubber products. We have the ability to design and manufacture custom rubber grommets and custom polyurethane bushings to fit your specific application in any shape, size, and material. We specialize in high precision tolerances, but also manufacture to commercial and less demanding tolerance configurations as well.

Seal Science is an industry leader in custom rubber products. We have the ability to design and manufacture custom rubber grommets and custom polyurethane bushings to fit your specific application in any shape, size, and material. We specialize in high precision tolerances, but also manufacture to commercial and less demanding tolerance configurations as well.

Rubber bushings are used to reduce vibration, absorb shock, and resist abrasion in an assembly. Custom polyurethane bushings are widely used in the automotive industry because of their added high load bearing capacity, high tear and cut resistance, resistance to water, grease, oil & ozone, and a higher compression set.

Bushing Materials

Our custom rubber products can be made in a wide range of materials: silicone, Fluorosilicone, polyurethane, EPDM (Ethylene Propylene), fluorocarbon, nitrile, neoprene/chloroprene, natural rubber and more. You can provide the drawing and specifications for your part, or we can design a custom molded product to fit your requirements.

Each of these materials has its own unique place within the sealing industry and each has benefits or downfalls depending on the application. If you are unsure which material would be best for your specific application, contact us and we will be able to point you in the right direction.

Click here for more information on our most widely used rubber materials.

Click here for a detailed table with Chemical Compatibility Information.

Visit our Material Selection Guide for seals and gaskets here.

Seal Science is also structured as an engineering support organization. We can provide application and manufacturing solutions for a wide range of industries. SSI incorporates design engineering, material science, and mechanical and physical property testing in our engineering methodology. Seal Science also utilizes 3-dimensional solid modeling and finite element analysis (FEA) when required for more critical applications. Check out this page for more info on our design capabilities.